2900 Series Variable Flow static mixers are designed for applications where the process flow varies significantly between low flows and high flows.

Examples of applications with extreme ranges of flow in which H2O Rx's Westfall static mixer are indicated are:

- A sleepy tourist town of 30 people for most of the year except during peak holiday periods where the tourist population swells dramatically;

- A reverse osmosis plant where multiple trains can be shut down depending on service requirements;

- Modern plants with variable speed pumps.

Traditional static mixers are designed to produce a head loss at a particular flow rate that translates to mixing energy. With the traditional static mixers, mixing energy reduces as flow decreases meaning the process is compromised at low flows..

Almost all modern plants have variable speed pumps allowing process flows to be optimised, but traditional static mixers cannot be designed to cope with this modern application.

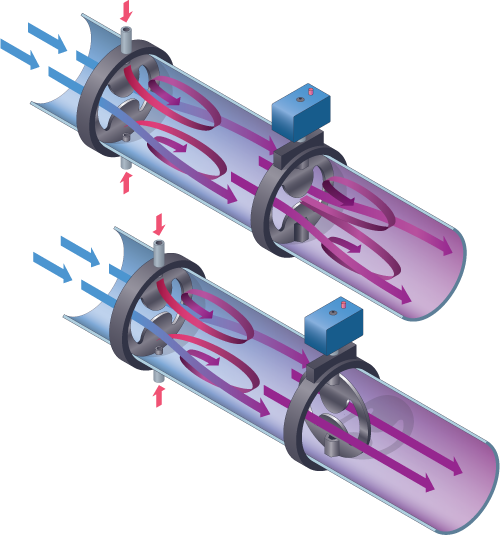

The 2900 Series Variable Flow static mixer employs the concept of the popular and proven 2800 Series Wafer-Style static mixer. It is comprised of two (2) off 2800 Series Wafer-Style static mixers - one fixed and one modulating that is built into a valve body.

During high flows, only the fixed mixer is required to provide optimal mixing, and then as the flow drops to very low flows, the variable mixer is engaged to provide optimal mixing (working in conjunication with the fixed mixer).

The 2900 Series Variable Flow static mixer can be modulating, step changing or manual.

This allows the 2900 Series Variable Flow static mixer to respond to changes in flow and maintain an optimised head loss over a much wider range of flows.

The advantages are:

- Mixes well for a wide range of flow rates without excessive headloss at maximum flow. No other static mixer can do this.

- High performance mixing - CoV of 0.05 or better.

- Published headloss - kV of 32.59 or better.

- Significantly reduces headloss at high rates of flow.

- Dramatically improves mixing at low rates of flow.

- Short laying length - two (2) off 2800 Series wafer-style mixer installed in a spool between two flanges

- Simple installation

- Material and freight costs are minimised

- Ports to connect to chemical injection assembles are built in to the mixer. Unless otherwise specifed.

- Sustainable - reduced maintenance or energy costs.

- Easy to clean

- Minimal or zero ragging

- CFD reports available

- White Papers available

| Series Brochure | Description | Diagram |

| Series 2900 | For mixing when the process flow rate varies significantly |  |

Westfall Static Mixers have predictable headloss co-efficients.

Click Here for a chart that indicates the head loss coeffient of each model.

Capabilities

H2O Rx is the exclusive Australian licensee and distributor of the Westfall Manufacturing range of static mixers manufactured in both Australia and USA.

H2O Rx and Westfall Manufacturing design and build static mixers to meet your application's needs:

Size Range: DN15 to DN3000

Materials Include:

- PVC

- FRP

- 316 stainless steel

- Carbon steel

- Titanium

- Kynar

- Teflon

Applications:

- All fluids - liquids and gases

- Municipal and industrial water treatment

- Potable water

- Waste water

- Irrigation

- Chlorination / dechlorination

- Chemical blending

- Dissolving gases

- Flocculent blending

- pH control

- Polymer blending

- Chemical Blending

- Dissolving Gases

- Contact Chambers

- pH control

Additional Resources

| Description | Downloads and Data |

| Animation showing the 2900 Series variable flow static mixer in operation. |

Last Updated: 25 February, 2026